Dust Collector & Ventilation System Design

Designing industrial dust collection, fume collection or ventilation systems starts with defining the characteristics of the material dust or fumes involved. Once the type of dust or fumes have been determined the calculations for ductwork sizing, required airflow, static pressure and the type and size of dust collector needed to adequately maintain a safe working environment for employees, can be determined.

Simple Dust Collector Calculations

A simple example of calculations required to mitigate welding fumes to ACGIH standards can be found on our Dust Collector System Design Calculations & Sizing page.

Dust Collection System Engineering

For most operations, the system design is not as simple as the example above and requires the expertise of a professional engineer – that is where we come in. The ventilation system design must take into account:

- The current layout of the plant

- Obstructions to ductwork

- Types of materials being collected

- Interactions between materials

- Possibility of explosion suppression systems being needed

- Interactions with currently installed air handling systems

- Requirements for an air makeup system

- The type of filtration material needed

- Duty cycles & required cleaning cycles of filtration material being used

- Intermittent or future processes being added to the plant’s operations

Our team of engineers is experienced in dust collection system design and capable of addressing all of the above, and more.

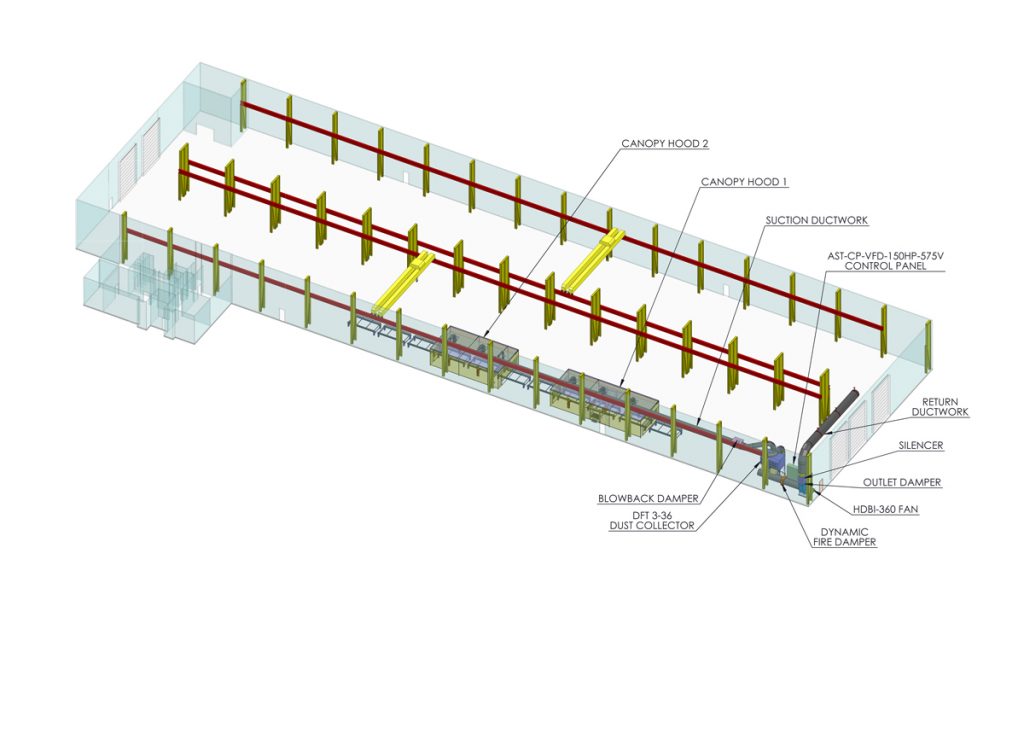

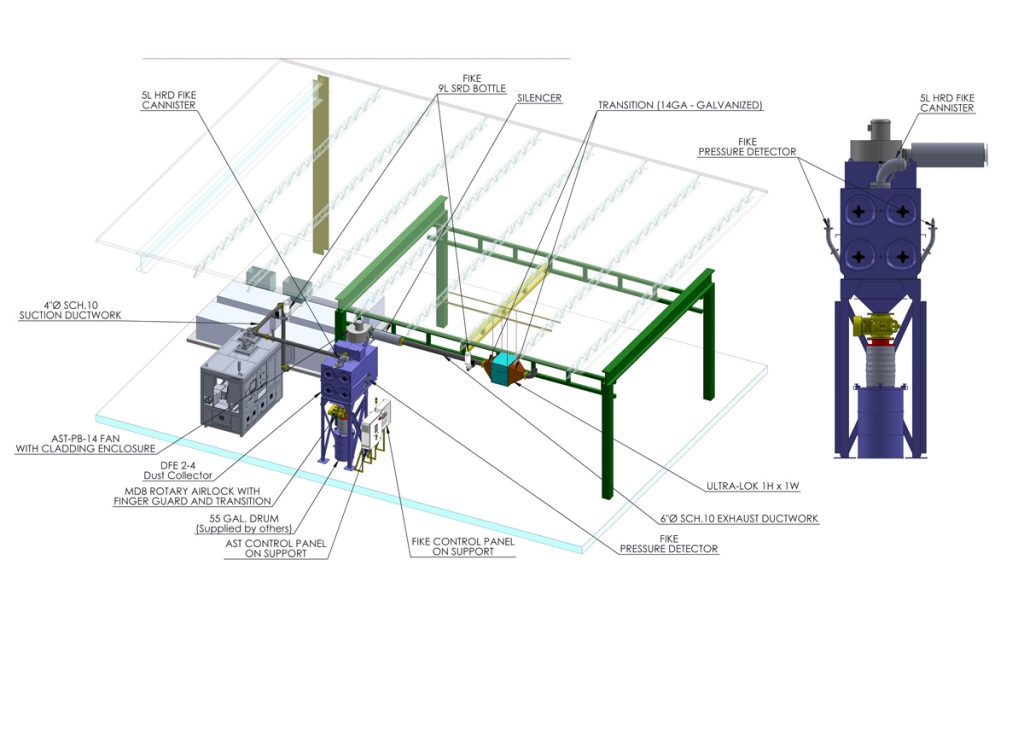

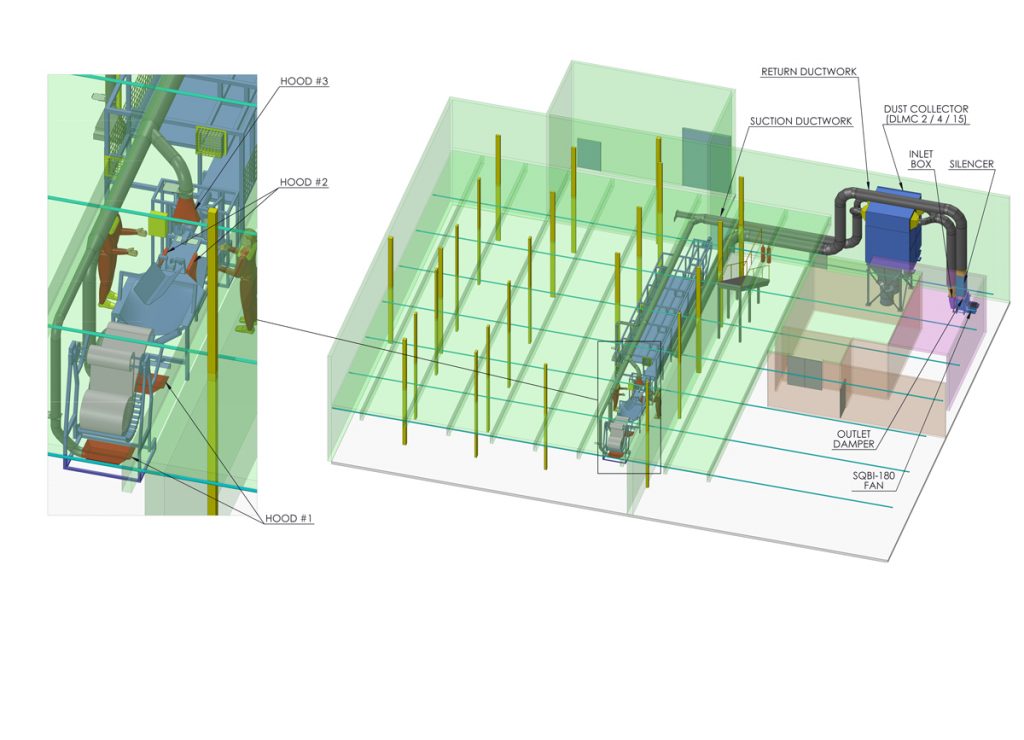

3D Modelling of Dust Collection Systems

One of the tools we use to make calculations for dust collector or fume collection system design is SolidWorks 3D Modelling software. By using our comprehensive library of solid parts, this design software allows us to generate 3-dimensional models of the proposed system. These 3D models are conceptual and help the designers, manufacturers, client and installers to have the same vision of the completed project. The level of detail in the models helps to streamline the installation process of the system.

Sample 3D Models

Click on the sample models below to view/download.